Product Name:Paraffins Preheating Rotation Dry Oven

Product Model: POL-101

Product Feature:Paraffins dedicated preheating rotation dry oven,printing ink preheating dedicated large-scale customized dry oven,large-scale customized rotation dry oven, printing ink industry rotation dry oven,preheating dedicated printing ink rotation 300 centigrade dry oven,printing ink/paraffins/steel,copper,aluminum mould dedicated large-scale customized preheating rotation dry oven,copper mould rotation dry oven, copper mould industrial oven, steel mould electric heating preheating dry oven,300 centigrade large-scale customized steel mould rotation drying machine, aluminum mould dedicated preheating dry oven.

Product Details:

Paraffins dedicated preheating rotation dry oven

Paraffin section step:1.Draw materials and fixation;2.Dehydration and transparency;3.Waxdip and embedding;4.Slice;5.Paste slice;6.Dry the slice and dewaxing;7.Dyeing(HE).It should dry at 90 centigrade for half an hour in dry oven when paraffin section.

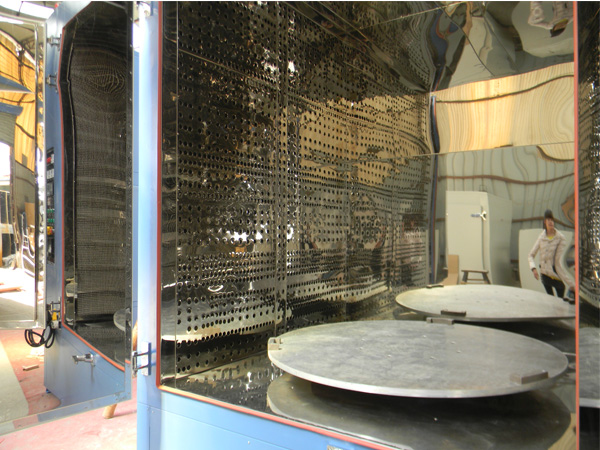

1. Large-scale customized rotation dry oven model: POL-101

2. Large-scale customized rotation dry oven specification and dimension:

Internal dimensions: D1500mm × W1500mm × H2000mm

External dimension: D1720mm × W2300mm × H2410mm

3. Air supply mode:Forced air supply circulation

4. Heating rate: RT+40℃~Max300℃,it needs about 55~60 minutes to reach to 250℃(no-load).

5. Max temperature: 300℃

6. Uniformity:Temperature tolerance is ±2.5℃((no-load) when temperature setting at 250℃.

7. Thermal insulation property:Extine temperature not exceeding 45℃(Room temperature +5℃),when the inside temperature reach to 250℃.

8. Airduct design:Adopts two sides airduct and top airduct circulation integrating,double door,the door holder adopts pull rod fixation,foaming high temperature resistant silicon gel sealing strip seal,different air deflectors be installed in two sides airduct.which make the air output volume can be controlled,and it make the inside temperature more uniform.

9. Large-scale customized rotation dry oven structure:The aluminum solid disk(diameter 1300mm, Thickness 22mm) will be installed at the chasis of the dry oven inside.It can load-bearing 800KGS or more.Use diameter 80mm spindle support transmission, transmission power is 0.75KW variable-frequency and variable-speed motor will be installed at the control cabinet,the chains drive.

|